Industrial - Bachelors

AD.PERF.RUN.

The AD.PERF.RUN. is designed to propel footwear standards in function, design and production sustainability.

Industrial - Bachelors

The AD.PERF.RUN. is designed to propel footwear standards in function, design and production sustainability.

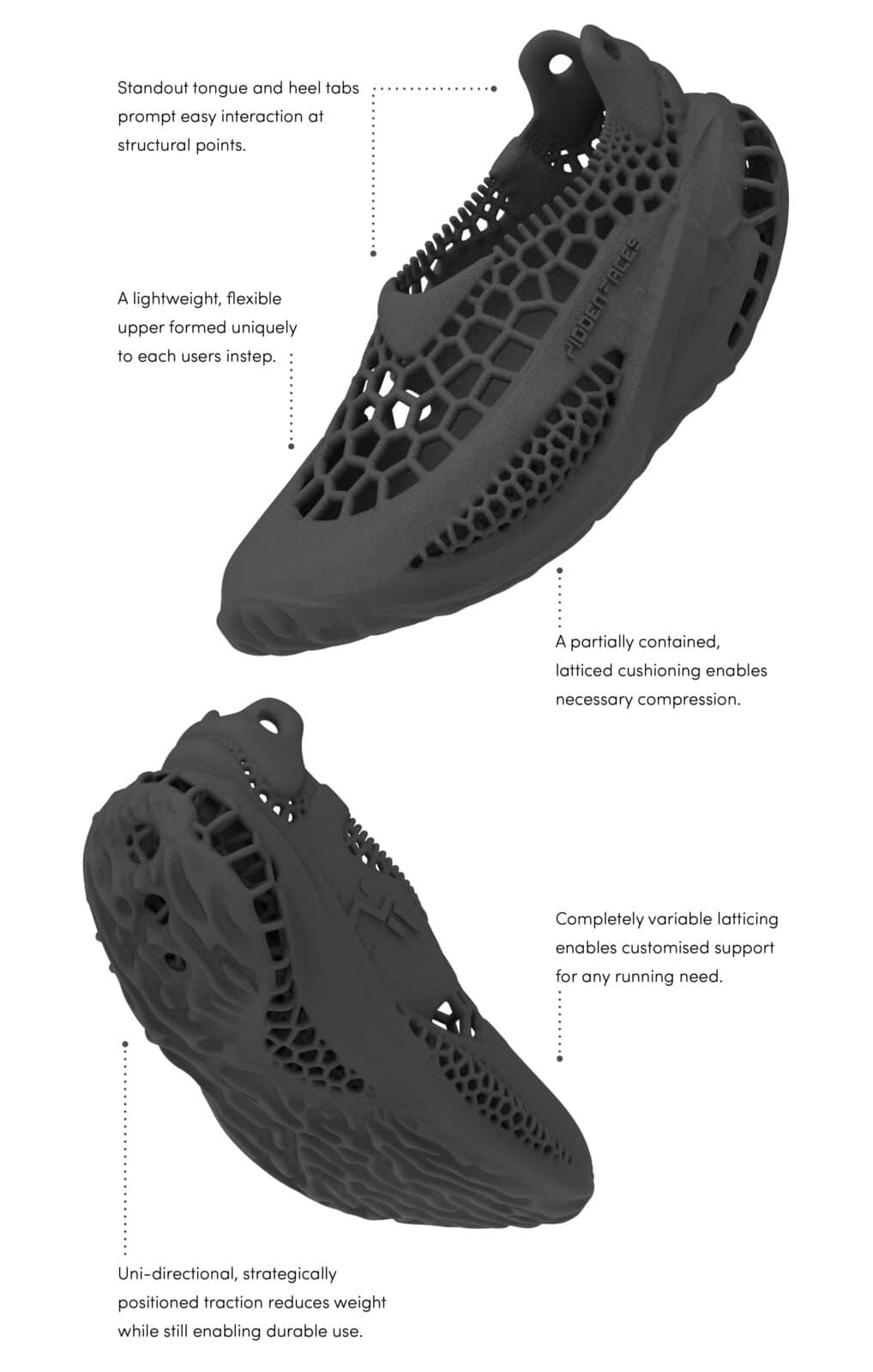

A rocker silhouette promotes quicker transition to toe-off and a mid-forefoot oriented landing. A dense, springboard forefoot mimics barefoot feel for body response.

The templated design of AD.PERF.RUN has also been configured to facilitate customization by podiatry recommendation, as incorporated into the services provided by local Brisbane podiatry manufacturer iOrthotics.

But is stagnated by its pursuit of efficient mass production, a dense horizontal supply chain, and the adoption of fast- fashion production cycles.

These complexities of mass-scale footwear production currently create scope difficulties in achieving sustainability.

Polarizing global standards, the Australian footwear industry is declining.

Major market segmentations in leather are losing popularity with changing consumer opinions. Three of the five major suppliers to Australian footwear are notable contributors to unsustainable practice: Beef Farming, Leather Manufacturing, and the Metals industries (Wheeler, 2023).

Despite this, Australia is still well positioned for change, with prominent segmentation supporting the application of cleaner practices in design, materials, production and disposal.

AD.PERF.RUN implements advanced data collection and additive manufacturing methods to create personalized footwear solutions.

Can be conducted by user through lidar enabled smart phones. or in podiatry consultation for special circumstance. This enables completely personalized shoe lasting.

Systems including Stereolithography and Selective Laser Sintering are enabling complex 3D printing without conventional support issues encountered in Fused Deposition Modelling.

Organic Cellulose based Thermoplastic-polyurethane is being developed from up to 70% plant-based material, is completely recyclable and short span biodegradable; and is performing the same or better than petrochemical based alternatives in footwear applications.

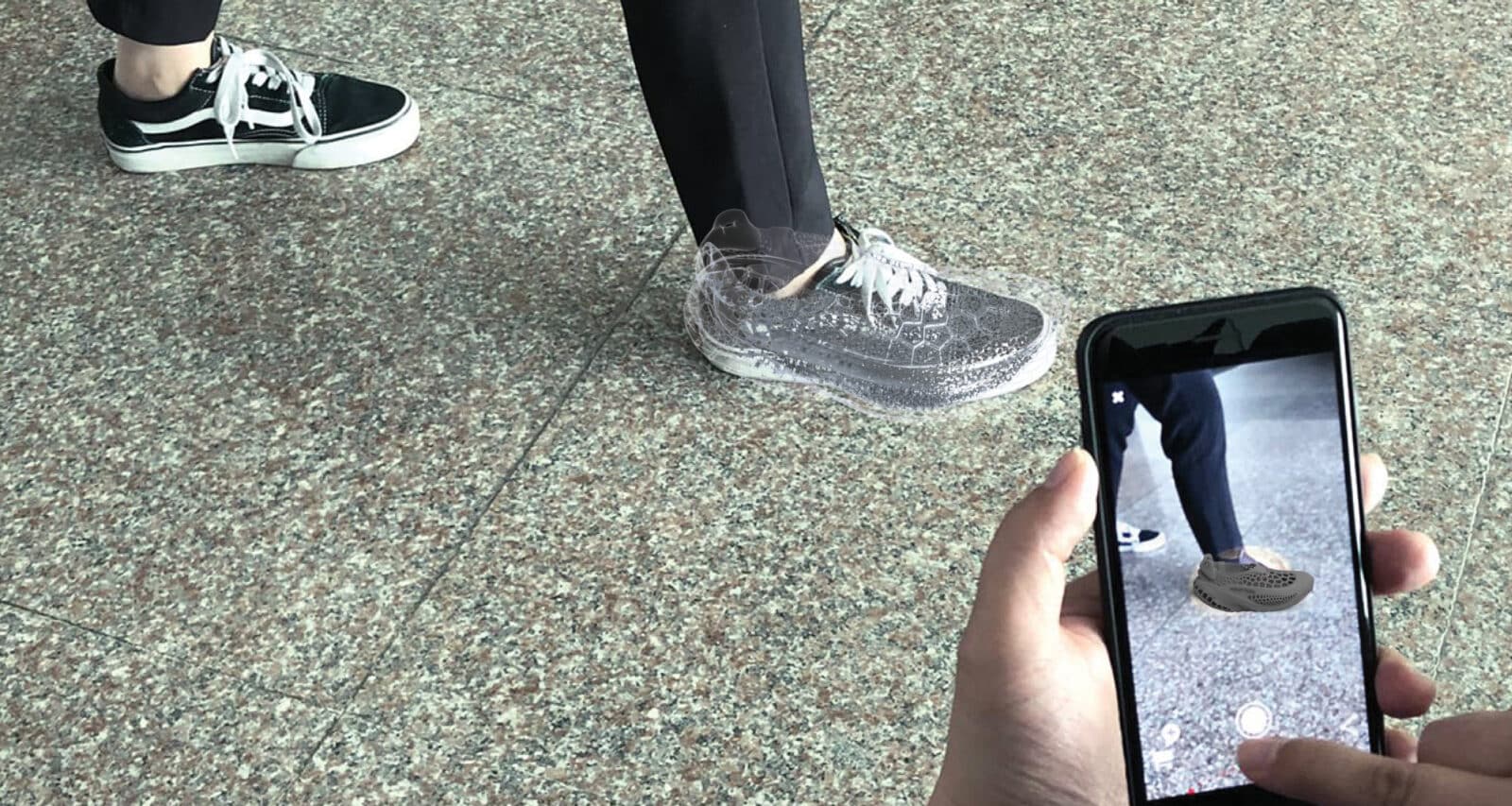

In consideration of sustainability and Australian industry, AD.PERF.RUN sits within a service system that leverages clean materials and design development, alongside a condensed supply chain. This is supported by an engagement system that aims to close the preference gap of consumers who are wanting to confirm comfort and feel, yet still prefer to purchase online.

Primary research was conducted for this project, identifying through survey that Australian runners highly value fit and feel in pre-purchase qualifying, yet also prefer to purchase online without try-on. This impedes purchasing confidence when engaging in online platforms.

AD.PERF.RUN can be purchased online through an internal platform that provides virtual try-on and fitting experiences, to communicate personalization and promote purchasing confidence without tangible testing.

The teaching staff throughout the course of my degree have helped me refine a hobby into a career skillset.

The information shared throughout this project has helped to inform better data collection and implementation methods, along with the necessary steps for creating a product that fits into Australia’s existing podiatry and athletic markets.

The internship period I had during my studies at Adidas HQ helped me to develop industry knowledge and design approaches that have propelled my abilities in the last year.

Sorry for talking about overly technical shoe things all the time. it likely won’t stop.

This project concludes my Bachelors degree in Industrial Design.

Following this I am now seeking full-time roles in the footwear industry globally.

Please feel free to reach me at

mstevens94@outlook.com

or my provided social media platforms.

Michael is a multi-disciplinary designer focusing on footwear innovation and function. Through previous pursuits, Michael has extensive experience in sports, business, construction and technical drafting; along with a passion for sustainability, abstraction and biomimicry. This combination has resulted in a design style that aims to push pragmatism, explore systems, and improve norms.