background

Mobile pollination plays a key role in almost every aspect of food production, and has an annual revenue of many hundreds of millions of dollars in Australia, and billions worldwide. Different parts of the world manage hive transportation differently based on culture and climate, but the Australian beehive transportation industry faces unique challenges – primarily due to our warm climate and significant distances between pollination locations. There’s all sorts of considerations to take in when thinking about hive transport – bees have quite specific temperature and humidity requirements, they don’t like being shaken around a lot (which presents a clear challenge in mass hive transport), they can only be transported during the night, among many other things. Considering these, and the fact that many of our transportation and hive management techniques are based on outdated and foreign systems, the industry has plenty of room to improve.

Research & Findings

Design Research Report

Survey

In order to gain some initial data, a survey targeting beekeepers of various scales from home beekeepers to employees of larger operations was deployed. Questions pertaining to years of beekeeping experience, number of hives managed, vehicle/s used to transport hives and other were asked. This data was recorded and themes certain common themes were identified.

One of the key findings of this survey was that the largest age demographic of survey participants was 40-79 years, suggesting many beekeepers could be particularly susceptible to the health impacts of repetitive strenuous tasks involved in beekeeping. An older beekeeper may develop conditions such as arthritis and RSIs, or have existing conditions exacerbated by tasks related to hive inspection and transport. The survey also indicated that participants can be responsible for the management of up to hundreds of beehives, as well as the inspection of thousands of individual frames between each hive.

Talk-Aloud Protocol

As part of the research process, a talk-aloud protocol was conducted at QUT’s Samford Valley ecological research facility with Dr. Dan Cook, where he demonstrated activities and techniques involved with hive management and transport – loading, unloading, dismantling etc. – while verbally describing what he was doing and pointing out actions he found particularly easy or difficult. This was a highly effective way method to understand the hive inspection process and identify design opportunities firsthand.

A wooden frame full of stinging insects is not something you want to lose your grip on.

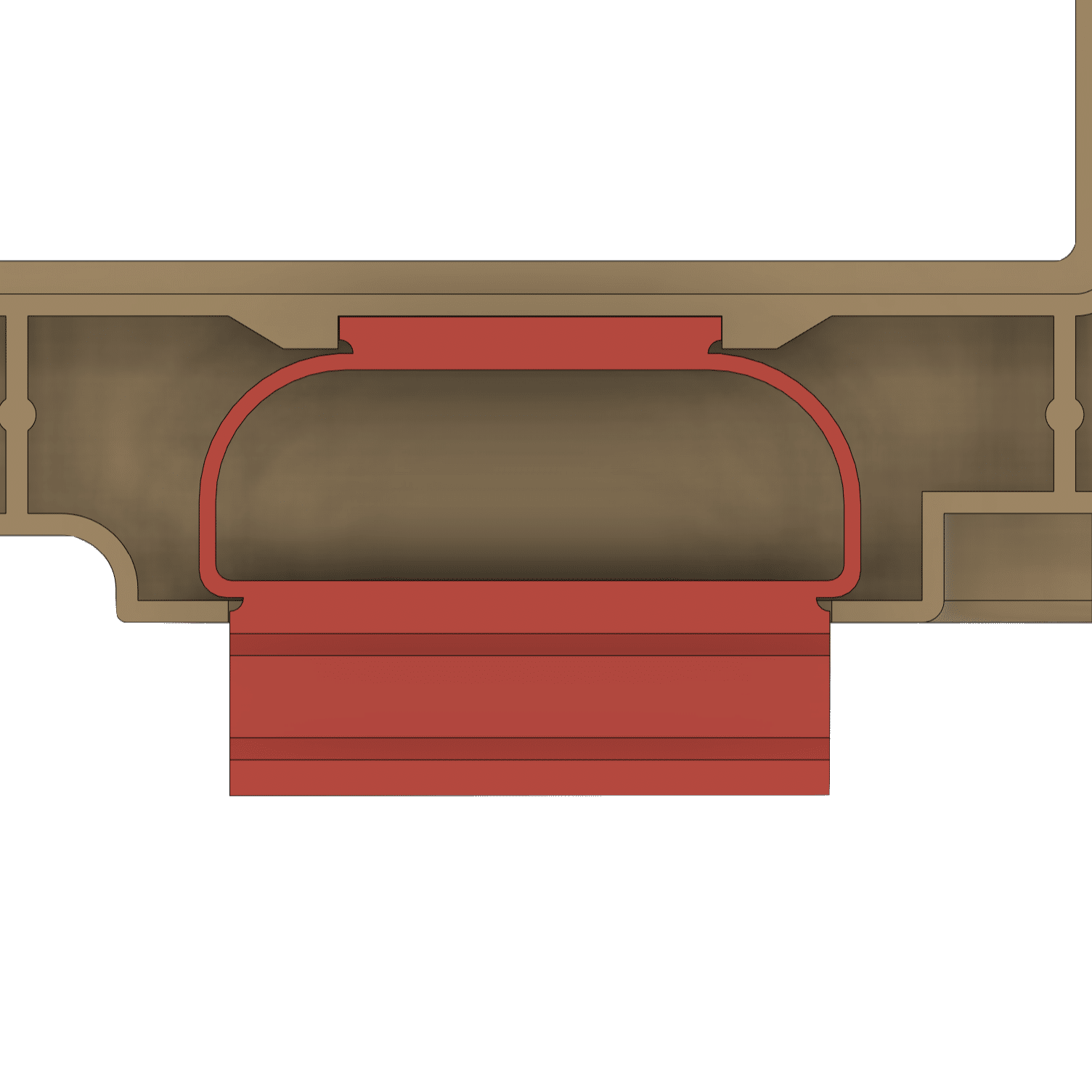

The current standard frame is essentially a wooden rectangle containing a beeswax foundation and it goes without saying it’s not especially ergonomically optimized for repetitive use. The inspection procedure involves manually detaching any buildup between the frame and hive, before lifting the frame by the lips designed to suspend the frame above the bottom of the hive. Due to the small surface area of these lips, the inspector must lift and manipulate the frame while aloft using a firm two- or three-finger grip, making each frame difficult and labour-intensive to inspect.

There are existing procedures for this kind of inspection, but most beekeepers either aren’t aware of this or choose other methods to save time, leading to neck craning, back strain and damage to the frames themselves.

Design Implications & Direction

Some key design directions drawn from the research include designing the final product to minimize weight and lifting awkwardness, improving the ergonomics to make it more suitable for repetitive use, and creating a solution that can be easily and accessibly applied to current industries of all sizes.

Design