How to improve safety and efficiency within the hospitality industry?

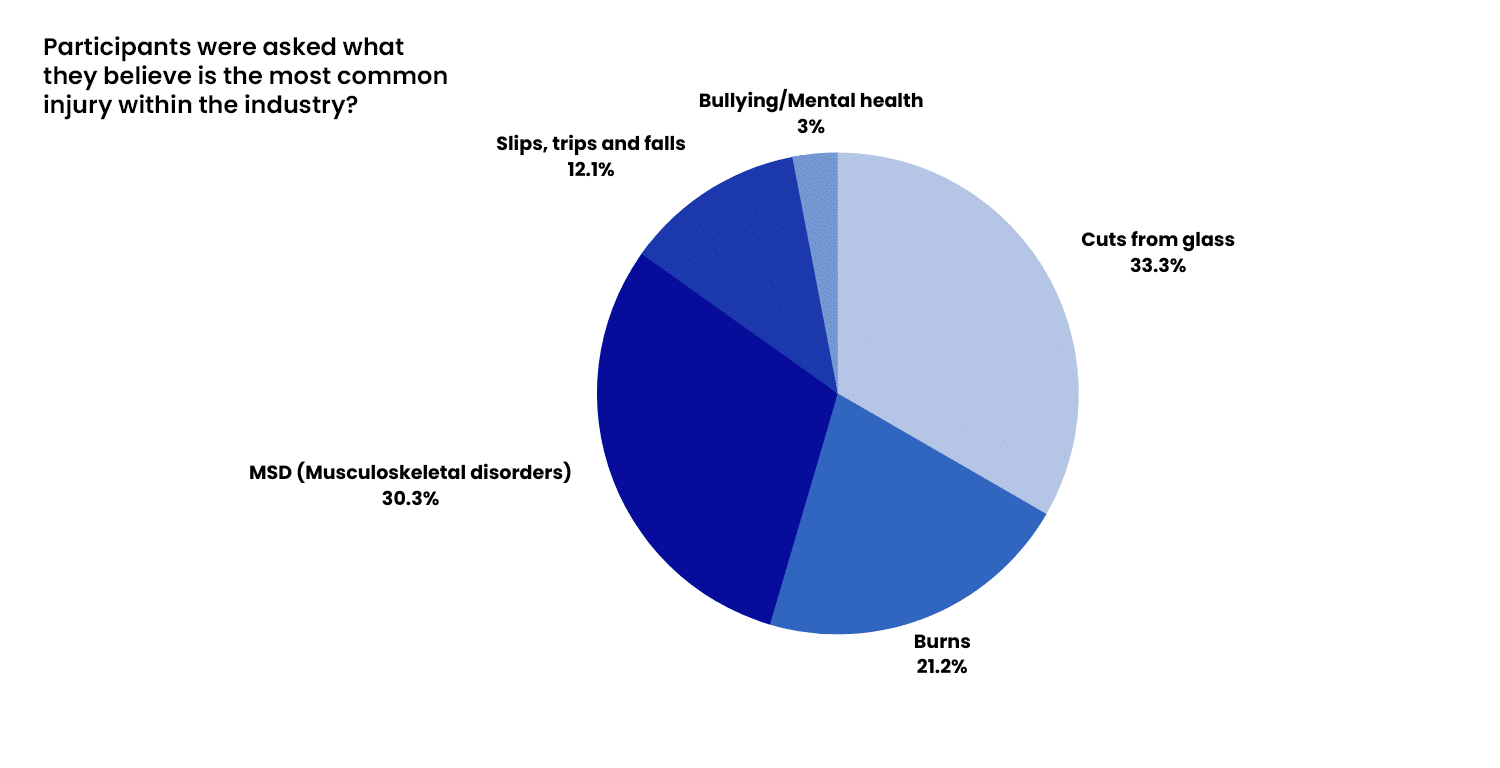

For my project I wanted to improve the safety and efficiency of the hospitality industry in some way shape or form. I started off with conducting some surveys and interviews to find out exactly what were some of the biggest injury concerns within the industry.

Through my survey I was able to learn that a majority of all injuries within the industry result from cuts from broken glassware. From the survey it was discovered the main cause for glasses breaking was due to them falling or sliding off drinks trays. Secondary research guided me to learning that the reason this is such a dangerous problem is that these cuts from broken glassware can cause infection such as sepsis, cellulitis and nerve damage. So from this information I knew what problem I wanted to address and I also knew that I could improve this problem through the form of innovation on the drinks tray.

Design solution

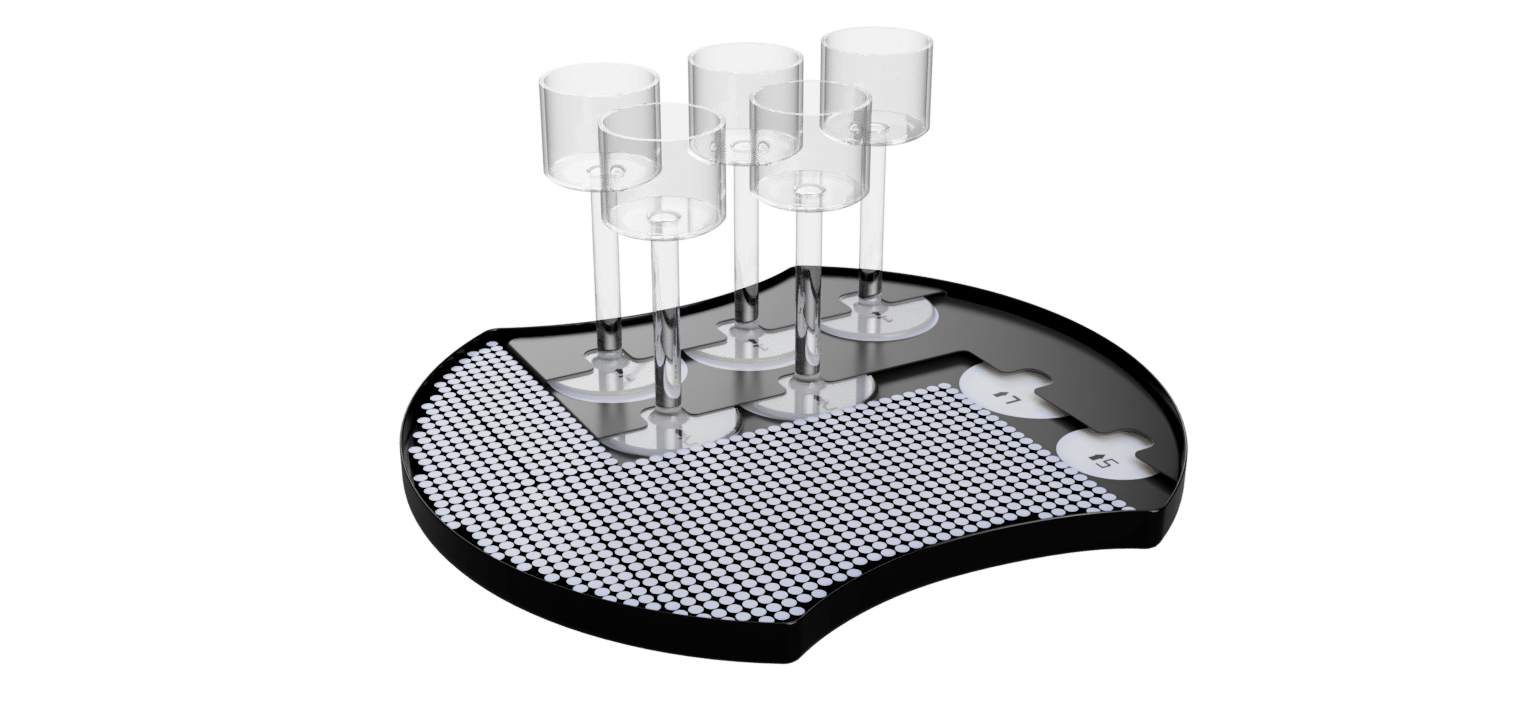

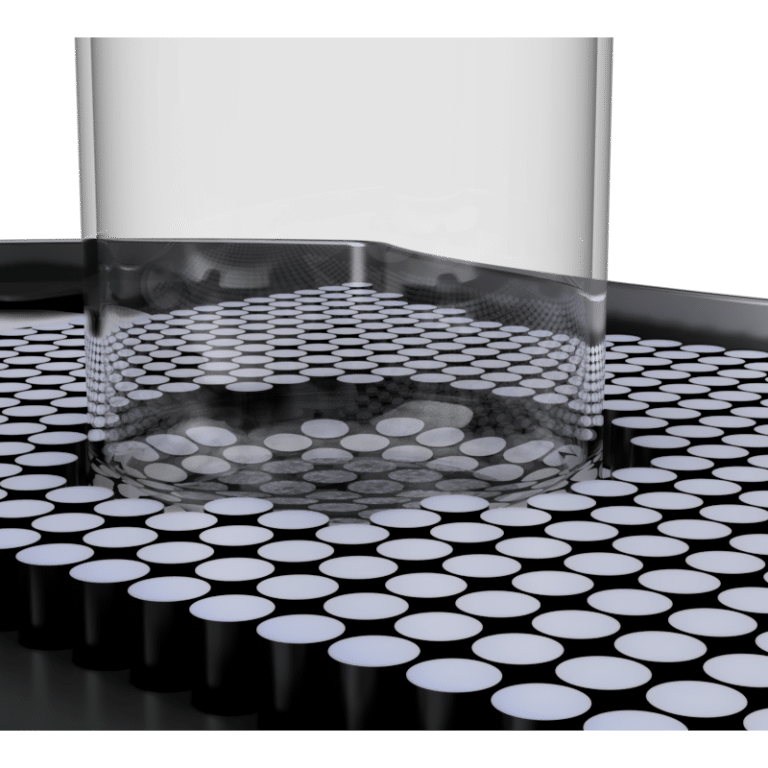

This is the Safe – Tray. A new and improved drinks tray that allows the user to hold onto glassware more safer and efficiently. On one side of the tray as seen above is a wine glass holding rack that allows the user to slide glassware into it and stops the wine glasses from sliding or falling over over. Where the wine glasses slide in are indicators showing the user in which order they should slide the wine glasses in to use the tray most efficiently.

Ergonomic shape

Another adjustment to the drink tray made was by giving it a more ergonomic shape. The ergonomic shape implemented is too give the user the ability to hold the tray closer to their body and in turn closer to their center of gravity. How this would look can be seen above within the context render. An indent was made on either side of the tray to allow the user to hold it from the side they plan to get the most glassware with, so if they plan on getting wine glasses more than round based glasses they would hold it from the indented side closer to the wine glass racks as this would allow them to hold the wine glasses closer to their body and in turn closer to their center of gravity. The same can be done vice versa for round based glassware.

For a more indepth look at how this tray works please view the video below

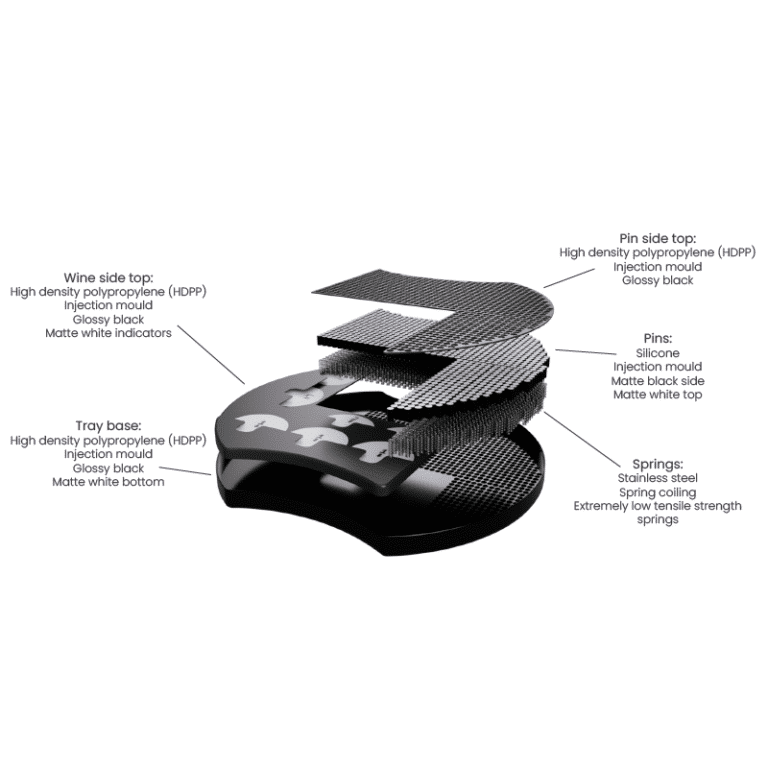

Manufacturing

Overall impact

The Safe – Tray aims to lower incidents involving broken glassware by reducing chances of glasses falling off of drinks trays and in turn decreasing the number of workers getting deadly infections caused from these cuts. Through reducing these workplace injuries, the Safe – Tray aims to create a safer and more efficient hospitality industry for all workers and guests alike. Furthermore the Safe – Tray has the potential to provide cost savings of upwards of $10,000 a year on broken glassware and workers compensation depending on the size of the hospitality venue.

A Happy Employee is a Productive Employee

Erin Davis

Files for viewing

Below links direct you to my research report which was used to find the problem for my design solution to resolve. There is also a link to the final specification report and bill or materials if you would like a more in-depth look into how this would be manufactured. I would of liked to have attached my DDR though it exceeded the maximum file size allowed, even at maximum compression. If you are at the design exhibition on the 15th please feel free to come have a look through my physical DDR.

- Name

- Research report: Improving safety and efficiency within the hospitality industry

- File Type

- application

- File Size

- 3 MB

- Link

- Download File

- Name

- Bill of materials: Safe – Tray

- File Type

- application

- File Size

- 179 KB

- Link

- Download File

- Name

- Specification report: Safe – Tray

- File Type

- application

- File Size

- 2 MB

- Link

- Download File

In the picture above you can see the user tilting the tray without any movement made by the glassware. This can be seen more in depth in the video above.